Slitter blades are mainly used for slitting paper, tape, magnetic tape, film, gold, silver, copper, aluminum, alloy foil and other items. The round blade forms a round shape. Generally, the round blade is used in mechanical equipment, mainly for cutting, trimming and other processing functions. The circular blade usually has a central hole, the purpose is to make it fixed on the mechanical equipment, so as to achieve the cutting function. So what are the tips for choosing the circular blade of the slitter?

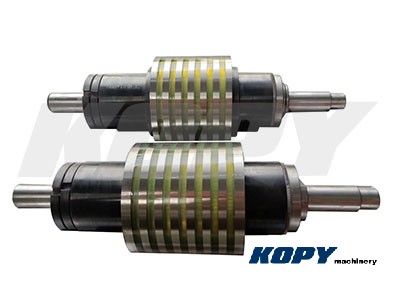

Slitter round blade

1. At present, due to the continuous increase of the scale of the enterprise, the production of some large-scale enterprises may reach thousands of pieces of circular cutting blades for production; , Without affecting the processing efficiency, the use of tools with low cost and high service life can save a lot of tool purchase costs for enterprises, which is conducive to reducing production costs.

2. Under normal circumstances, the longer the use time of the slitting circular blade, the greater the impact on saving production time. Therefore, under normal circumstances, high-quality wear-resistant products are the products that companies purchase more, followed by higher precision and size. of knives and products at reasonable prices.

3. In addition, due to the difference in processing speed of modern machine tools, tools with high wear resistance and precision are often suitable for high-speed slitting equipment, while low-speed machine tools do not need such tools, and efficient production cannot be improved by using high-efficiency tools. Therefore, when choosing tools, enterprises should choose products that can achieve good processing efficiency.

4. Generally speaking, high-quality slitting circular blades are suitable for large-scale slitting production, while small-batch processing can use products of lower quality, which can reduce part of the data procurement cost and create better economic benefits. At present, with the popularization of CNC machining, the precision requirements of tools are becoming higher and higher, and the CNC machining technology has potential advantages, which can greatly reduce the workload and improve the processing efficiency.

Therefore, when choosing a slitter blade, it must be a blade that is suitable for the machine. You cannot one-sidedly and objectively pursue imported blades, but ignore the blades that should be matched with your own model.

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.